The German group Claas has a plant in Le Mans, Atlantic France, which manufactures high-quality tractors. Over the last years, €40 million have been invested to transform the site into an industry 4.0 factory combining robotics, IoT and virtual reality.

700 people work in the Claas agricultural machinery factory located in Le Mans. More than 70% of its production is exported worldwide. In 2020, the group’s annual turnover exceeded 4 billion euros for the first time in its 90-year history.

Since 2017, an ambitious programme called “Claas forth” has been undertaken to modernise the factory in Le Mans. More than €40 million have been invested to transform the site which has been labelled “Showcase for the Industry of the Future”.

Improving both efficiency and comfort at work

First of all, a new production line has been in operation since September 2019. The employees are now assisted by 36 automated guided vehicles which can carry up to 20 tons, and many digital technologies such as IoT.

The main objective is to increase the production from 50 to 75 tractors per day. But these innovations are also improving the working conditions, and in addition the inside of the Claas factory in Le Mans was painted entirely with clear colors to gain luminosity. 250 tons of paint was needed!

Two virtual reality rooms and a test bench

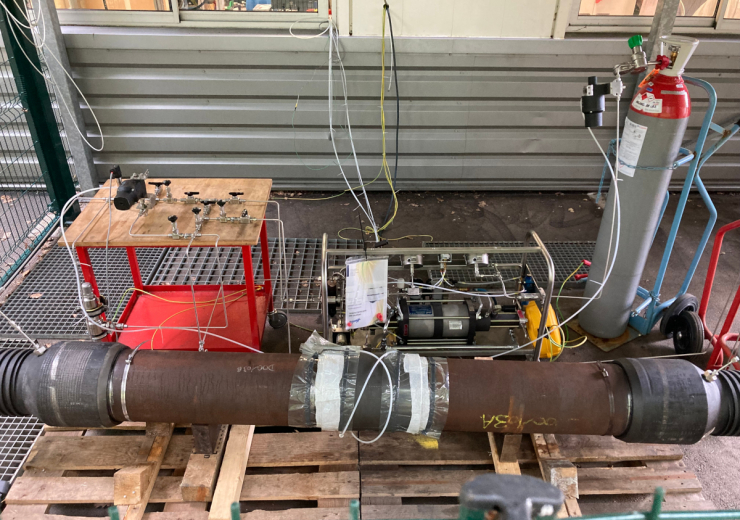

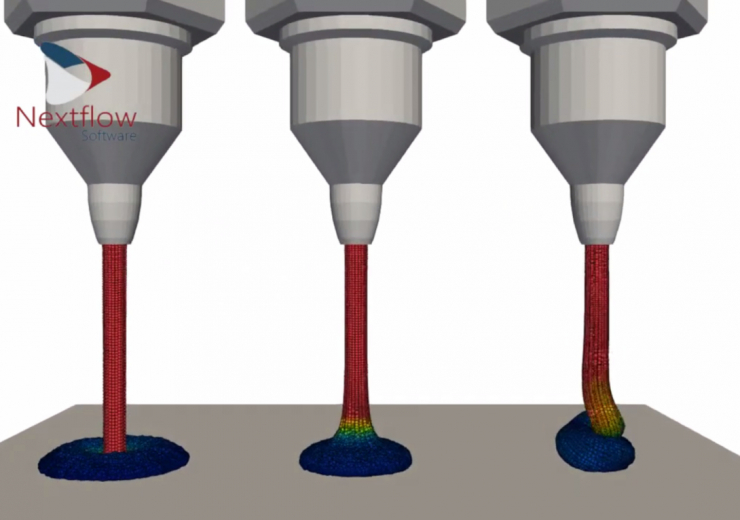

Last but not least, the plant hosts two virtual reality rooms which can be used for training, project simulation or improving the ergonomics of workstations. A test bench will be installed soon and the transformation programme of Claas’ factory in Le Mans should be completed by May.

日本語

日本語  Français

Français